Food

Food

Food

Vegetables, Salads, Precooked meals, Meat, Algae,

Seafood, Fish, Fruits & Flowers

Vegetables, Salads, Precooked meals, Meat, Algae, Seafood, Fish, Fruits & Flowers

Vegetables, Salads, Precooked meals, Meat, Algae, Seafood, Fish,

Fruits & Flowers

The Standard Products

- We offer cooling tunnels with a capacity of 4, 6, 8, 10 and 12 pallets. 1 pallet can hold approx. 1 ton of merchandise

- Cycle time span is 15 minutes on average. It depends on the product, not the temperature gap

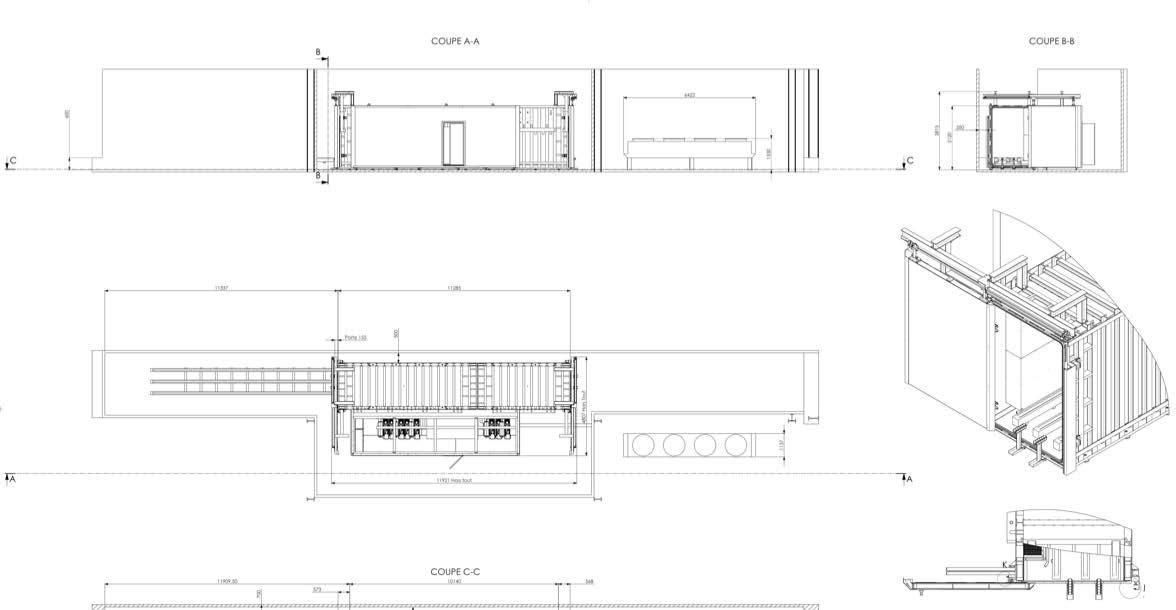

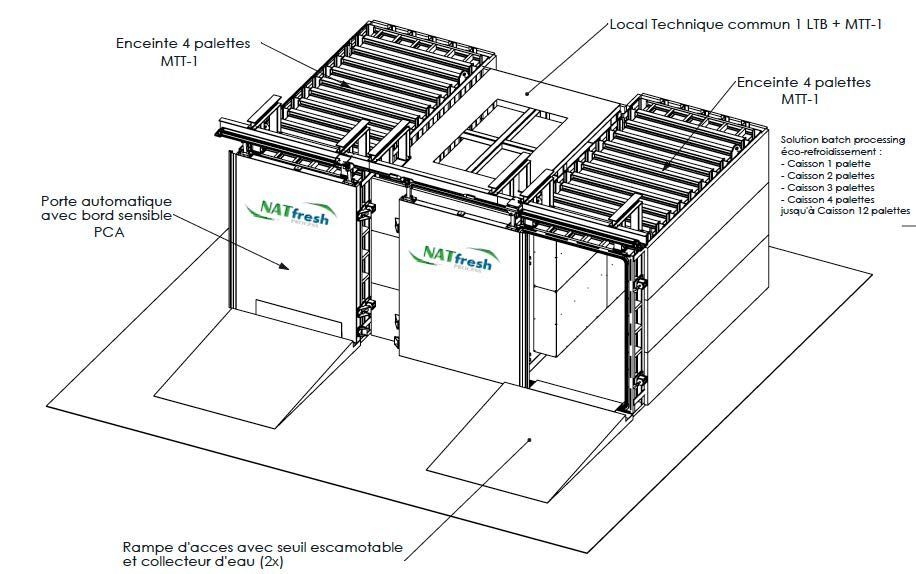

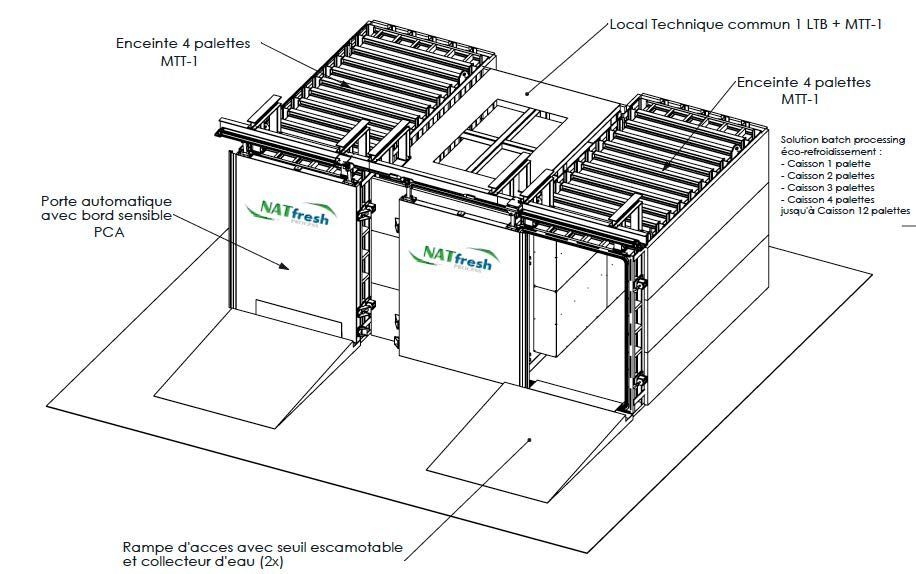

- A 4-pallet system with one tunnel can cool approx. 8 tons per hour with a 15 minutes cycle and 16 tons per hour with a double tunnel like shown below in the blue print

- Size: Approx. 8 × 8 × 3 meters for a 4-pallet system with a double tunnel

- The biggest system built so far has 12 pallets, 48 tons/hour production capacity

- Energy consumption is always 7,5 kWh per ton

- Energy costs per ton: 1.55 USD/ton @ 0.20 USD/kWh

While one chamber is being loaded, the cooling process is in full swing in the second chamber (Fig. 2). In 15 minutes, the four pallets with cooled goods can be unloaded again and reloaded with non-cooled goods. This rhythm allows 4 cycles of 4 tons per hour. This results in a production capacity of 16 tons per hour. The tunnels can be loaded manually or with conveyor belts.

The Standard Products

- We offer cooling tunnels with a capacity of 4, 6, 8, 10 and 12 pallets. 1 pallet can hold approx. 1 ton of merchandise.

- Cycle time span is 15 minutes on average. It depends on the product, not the temperature gap.

- A 4-pallet system with one tunnel can cool approx. 8 tons per hour with a 15 minutes cycle and 16 tons per hour with a double tunnel like shown below in the blue print.

- Size: Approx. 8 × 8 × 3 meters for a 4-pallet system with a double tunnel

- The biggest system built so far has 12 pallets, 48 tons/hour production capacity.

- Energy consumption is always 7,5 kWh per ton

- Energy costs per ton: 1.55 USD/ton @ 0.20 USD/kWh

While one chamber is being loaded, the cooling process is in full swing in the second chamber (Fig. 2). In 15 minutes, the four pallets with cooled goods can be unloaded again and reloaded with non-cooled goods. This rhythm allows 4 cycles of 4 tons per hour. This results in a production capacity of 16 tons per hour. The tunnels can be loaded manually or with conveyor belts.

The Custom-made Products

We build to your needs

- On-board solutions for fishing boats and large cargo ships,

- Solutions for optimizing the transport of ready-made meals on board of passenger aircraft

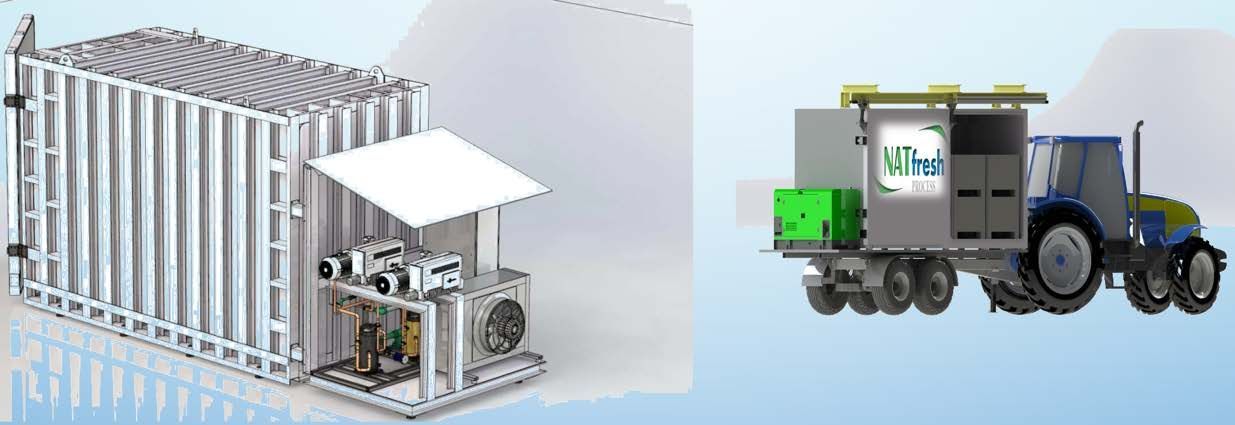

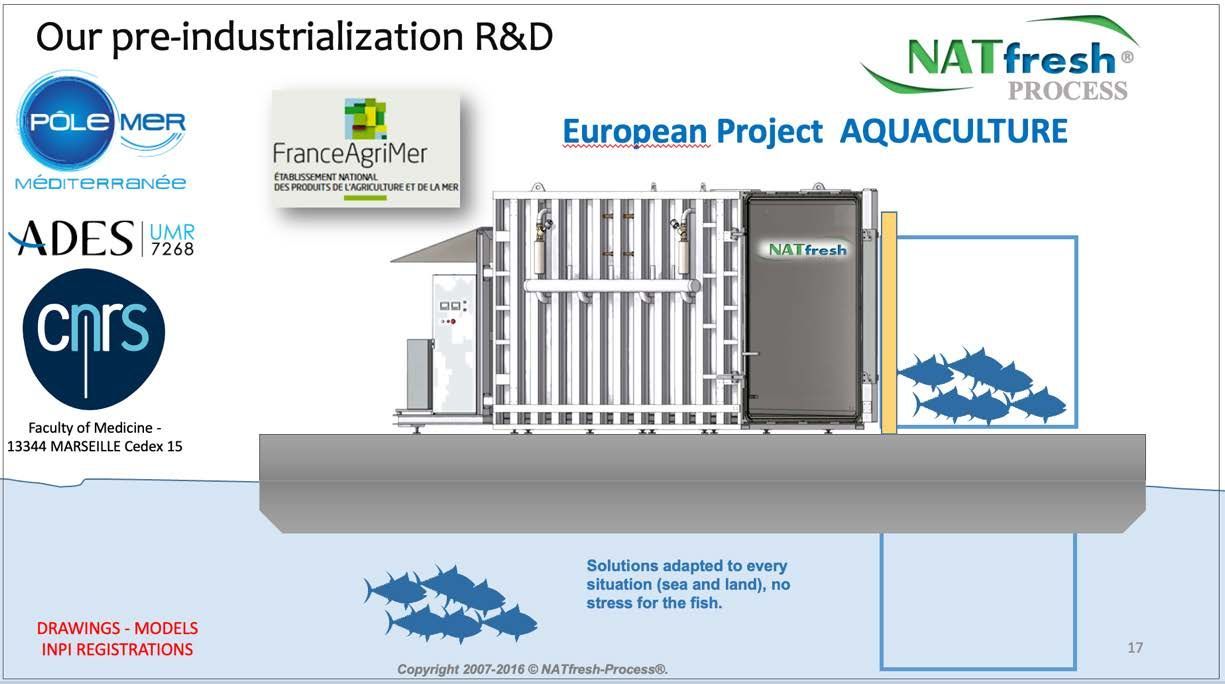

- Pilot installations or small formats that can be moved to the field (grape harvests, fisheries, freshwater and seawater fish farms)

- Solutions designed to be installed in a process, at the end of a slaughter line for poultry, rabbit, quail, etc.

- Solutions for ready-cooked, cooked or pre-cooked meal lines

The Custom-made Products

We build to your needs

- On-board solutions for fishing boats and large cargo ships,

- Solutions for optimizing the transport of ready-made meals on board of passenger aircraft

- Pilot installations or small formats that can be moved to the field (grape harvests, fisheries, freshwater and seawater fish farms).

- Solutions designed to be installed in a process, at the end of a slaughter line for poultry, rabbit, quail, etc.

- Solutions for ready-cooked, cooked or pre-cooked meal lines

Delivery of the 12-pallet system

Installed active production system in France

The goods are in the blue transport boxes loaded on pallets moved with conveyor belts