Perfect turgidity, a paradigm shift in cooling

Perfect turgidity, a paradigm shift in cooling

Perfect Turgidity,

a Paradigm Shift in Cooling

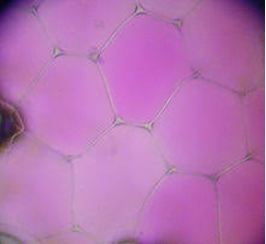

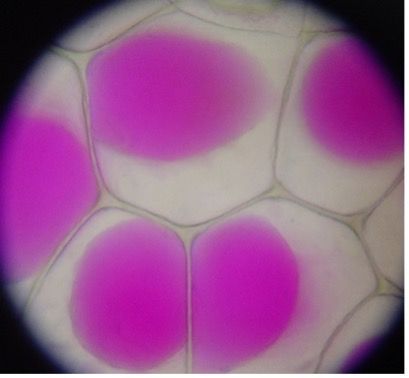

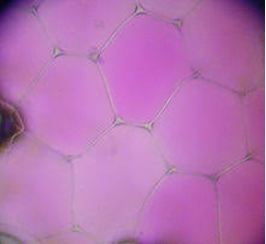

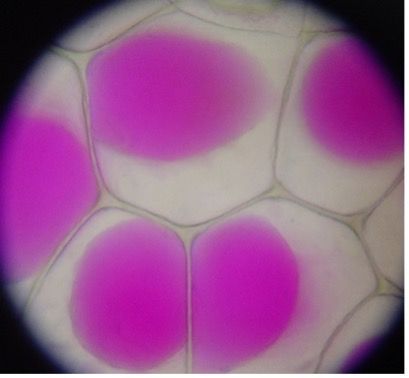

The Definition of Turgidity :

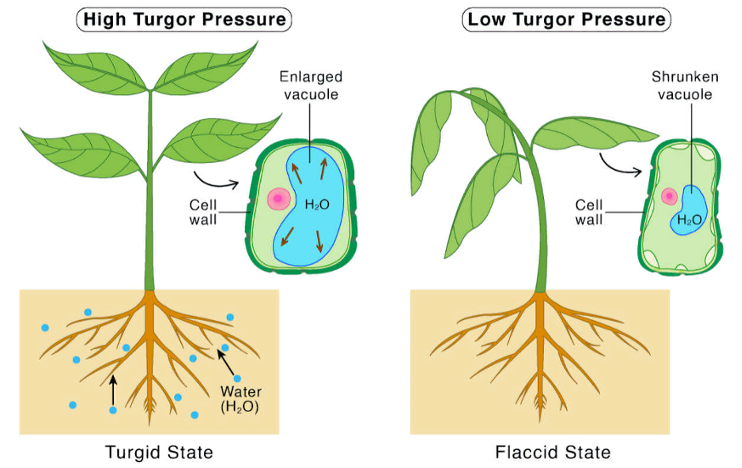

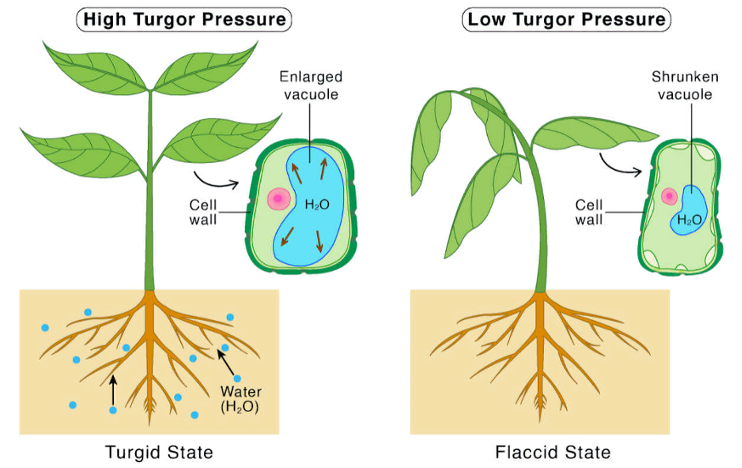

Turgidity is the swelling of a cell due to water penetration when immersed in a less concentrated (hypotonic) medium

Turgidity is the swelling of an organ or tissue due to venous blood retention

This cellular phenomenon of cell swelling is due to the absorption of water a highly fluid content. Cells absorb water, which is stored in vacuoles, causing them to swell. Turgidity occurs due to the presence of the cell wall and the osmoregulatory effect of the vacuole

It's also the state of the cell in which the cell wall has stretched to its maximum capacity, to the point where it can no longer accommodate new water molecules. The completely distended cell is called a turgid cell. Turgidity contributes to the growth and rigidity of plant parts such as leaves and stems

Turgor Pressure

The Definition of Turgidity:

Turgidity is the swelling of a cell due to water penetration when immersed in a less concentrated (hypotonic) medium

Turgidity is the swelling of an organ or tissue due to venous blood retention

This cellular phenomenon of cell swelling is due to the absorption of water a highly fluid content. Cells absorb water, which is stored in vacuoles, causing them to swell. Turgidity occurs due to the presence of the cell wall and the osmoregulatory effect of the vacuole.

It's also the state of the cell in which the cell wall has stretched to its maximum capacity, to the point where it can no longer accommodate new water molecules. The completely distended cell is called a turgid cell. Turgidity contributes to the growth and rigidity of plant parts such as leaves and stems.

Turgor Pressure

The choice of a pre-cooling and/or a cooling technique is essential when maintaining good turgidity quality, both post-harvest and also during transportation and storage

In a nutshell: The quality of the Turgidity defines the quality of the product

Most freezing processes damage the cell walls of products, producing an irreversible thermal shock. Traditional refrigeration produces cold by forcing cold to penetrate from the surface to the core of the product. This is done layer by layer, from the outside of the product to its core. This is called forced cooling. A cooling method that requires the use of high cooling power, but also continuous cooling power supply to maintain a temperature in a cooled volume. It seeks to saturate the cold in the cold storage room before shipment. This mode of operation can lead to edge burns at the ends of the leaves, but also to water loss (product hygrometry) between cold entry and exit, prior to shipment. The longer the storage time, the greater the water loss

On the other hand, and maybe even more important for the consumer, such cooling processes result in a typical product taste of frozen food and a lack of crunchiness. In the case of products cooled by this type of traditional technology, once they have been used by the cook to prepare a meal, they will release a quantity of water created during the freezing process and induced by this type of traditional cooling technique

Loss of weight means loss of revenue and bad product quality. Moreover, forced cooling generates high energy costs. The perfect formula for a loss-loss situation.

The choice of a pre-cooling and/or a cooling technique is essential when maintaining good turgidity quality, both post-harvest and also during transportation and storage

In a nutshell: The quality of the Turgidity defines the quality of the product

Most freezing processes damage the cell walls of products, producing an irreversible thermal shock. Traditional refrigeration produces cold by forcing cold to penetrate from the surface to the core of the product. This is done layer by layer, from the outside of the product to its core. This is called forced cooling. A cooling method that requires the use of high cooling power, but also continuous cooling power supply to maintain a temperature in a cooled volume. It seeks to saturate the cold in the cold storage room before shipment. This mode of operation can lead to edge burns at the ends of the leaves, but also to water loss (product hygrometry) between cold entry and exit, prior to shipment. The longer the storage time, the greater the water loss.

On the other hand, and maybe even more important for the consumer, such cooling processes result in a typical product taste of frozen food and a lack of crunchiness. In the case of products cooled by this type of traditional technology, once they have been used by the cook to prepare a meal, they will release a quantity of water created during the freezing process and induced by this type of traditional cooling technique.

Loss of weight means loss of revenue and bad product quality. Moreover, forced cooling generates high energy costs. The perfect formula for a loss-loss situation

Understanding Turgor

The quality of the turgidity enables a plant to grow in the right conditions, but also, if the turgidity is maintained once the post-harvest stage is over, and during pre-cooling or cooling, its preservation is guaranteed. Taking into account natural preservation, from transport to the consumer's plate, who can enjoy a fresh product, fresh from the field, or even from the greenhouse

Understanding Turgor

The quality of the turgidity enables a plant to grow in the right conditions, but also, if the turgidity is maintained once the post-harvest stage is over, and during pre-cooling or cooling, its preservation is guaranteed. Taking into account natural preservation, from transport to the consumer's plate, who can enjoy a fresh product, fresh from the field, or even from the greenhouse.

The central role of turgidity in plant cultivation

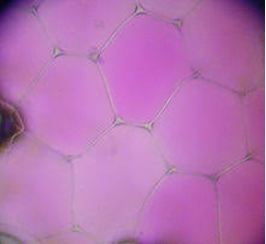

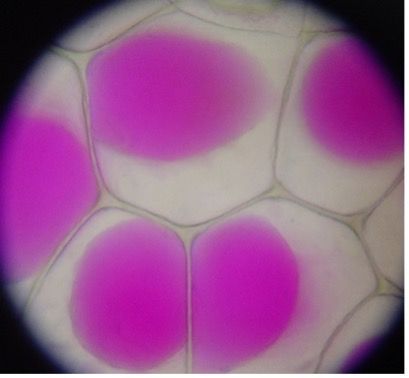

The presence of a semi-rigid wall and vacuoles in plants gives them the ability to have cells under pressure, known as "turgidity".

Some of the roles of turgidity have long been identified, such as beneficial for growth, upright habit, or controlling the opening of stomata (tiny openings in the plant's epidermis involved in the plant's respiration and transpiration processes).

The central role of turgidity in plant cultivation

The presence of a semi-rigid wall and vacuoles in plants gives them the ability to have cells under pressure, known as "turgidity"

Some of the roles of turgidity have long been identified, such as beneficial for growth, upright habit, or controlling the opening of stomata (tiny openings in the plant's epidermis involved in the plant's respiration and transpiration processes)

In recent years, a group of scientists have highlighted the existence of new turgor pressure functions that have been revealed or suspected at cellular and/or tissue level, such as during seed development or lateral root initiation

Turgor is also present at the molecular level, probably involved in the transduction of mechanical signals via

wall-associated proteins or mechanosensitive channels

Many of the roles attributed to turgor are, however, proven indirectly by the quantitative measurement of hydrostatic pressure in the cell or tissue under study. Moreover, the anatomy of multi-cellular organisms and the specific functions of each tissue suggest that pressures and their regulation vary from one tissue to another. Finally, the coupling between mechanical forces and tissue deformation, involving wall properties, adds a further element of complexity to the system

In recent years, a group of scientists have highlighted the existence of new turgor pressure functions that have been revealed or suspected at cellular and/or tissue level, such as during seed development or lateral root initiation.

Turgor is also present at the molecular level, probably involved in the transduction of mechanical signals via

wall-associated proteins or mechanosensitive channels.

Many of the roles attributed to turgor are, however, proven indirectly by the quantitative measurement of hydrostatic pressure in the cell or tissue under study. Moreover, the anatomy of multi-cellular organisms and the specific functions of each tissue suggest that pressures and their regulation vary from one tissue to another. Finally, the coupling between mechanical forces and tissue deformation, involving wall properties, adds a further element of complexity to the system.

Tests and experiments with NATfresh ® technology on a wide range of products confirm the beneficial effects on turgidity:

NATfresh® has spent many years carrying out tests and experiments on crop plants (in greenhouses and in the ground), as well as on a large number of product varieties (ready-made meals, pre-cooked and cooked products, products from slaughter lines, etc.), all of which have undergone The NATfresh® Technology process

These tests have confirmed unequivocally the great beneficial effects obtained on turgidity

These effects confirm the results, that turgidity is completely maintained with no loss of product water and it is sustained over a comprehensive cooling cycle, including between the product infeed and the product outfeed of the process

The Product passes through the NATfresh® Technology before being loaded directly onto the trucks. It is then dispatched for distribution to supermarkets and convenience stores

There's no longer any need for cold-saturated storage, as the temperature of the full-volume product passing through the machine during a cycle remains stable and homogeneous throughout

NATfresh® Technology

ensures that the turgidity is maintained, and the product stays fresh for much longer. We can speak of a deep sleep effect for the product, and the same for the turgidity. As a result, the product holds up well over time, even when transported over long distances

Tests and experiments with NATfresh ® technology on a wide range of products confirm the beneficial effects on turgidity:

NATfresh® has spent many years carrying out tests and experiments on crop plants (in greenhouses and in the ground), as well as on a large number of product varieties (ready-made meals, pre-cooked and cooked products, products from slaughter lines, etc.), all of which have undergone The NATfresh® Technology process.

These tests have confirmed unequivocally the great beneficial effects obtained on turgidity

These effects confirm the results, that turgidity is completely maintained with no loss of product water and it is sustained over a comprehensive cooling cycle, including between the product infeed and the product outfeed of the process.

The Product passes through the NATfresh® Technology before being loaded directly onto the trucks. It is then dispatched for distribution to supermarkets and convenience stores.

There's no longer any need for cold-saturated storage, as the temperature of the full-volume product passing through the machine during a cycle remains stable and homogeneous throughout.

NATfresh® Technology

ensures that the turgidity is maintained, and the product stays fresh for much longer. We can speak of a deep sleep effect for the product, and the same for the turgidity. As a result, the product holds up well over time, even when transported over long distances.

The main benefits of NATfresh® Technology

- The process causes

no spoilage and maintains balanced turgidity, considerably extending the shelf life of fresh foods

- The process

avoids the weight loss typical of standard cooling processes. Weight loss means loss of income, as most vegetables are sold by weight

- The outer leaves of the most fragile lettuces are

not burnt, so they retain their original weight, without reducing revenue. This also avoids any reworking of the produce on the packaging lines which

means less additional labor costs

- With NATfresh®, you can increase your revenues by drastically reducing the loss of products through spoilage. Whereas standard cooling processes are prone to product returns due to non-quality freshness

- Produce retains its taste, bite and crunch even longer than when freshly harvested. Your products are better than the competition. They stay longer fresh on distributor shelves

- In addition to the beneficial effects that NATfresh Technology brings to products and producers' revenue, it's also worth bearing in mind that the process reduces energy costs by 80% and requires a throughput time of just 15 minutes

The main benefits of NATfresh® Technology

- The process causes

no spoilage and maintains balanced turgidity, considerably extending the shelf life of fresh foods

- The process

avoids the weight loss typical of standard cooling processes. Weight loss means loss of income, as most vegetables are sold by weight

- The outer leaves of the most fragile lettuces are

not burnt, so they retain their original weight, without reducing revenue. This also avoids any reworking of the produce on the packaging lines which

means less additional labor costs

- With NATfresh®, you can increase your revenues by drastically reducing the loss of products through spoilage. Whereas standard cooling processes are prone to product returns due to non-quality freshness

- Produce retains its taste, bite and crunch even longer than when freshly harvested. Your products are better than the competition. They stay longer fresh on distributor shelves

- In addition to the beneficial effects that NATfresh Technology brings to products and producers' revenue, it's also worth bearing in mind that the process reduces energy costs by 80% and requires a throughput time of just 15 minutes

We believe that with these features improve product quality, with less waste, 80% less energy consumption and a faster production cycle greatly reduced to 15 minutes.

The NATfresh Technology represents a paradigm shift

in food cooling

We believe that with these features improve product quality, with less waste, 80% less energy consumption and a faster production cycle greatly reduced to 15 minutes.

The NATfresh Technology represents a paradigm shift in food cooling